High Pressure Combustion Lab

Dr. Richard Yetter, Director

104 Research Building East

University Park, PA 16802

Phone: (814) 863-6375

Email: ray8@psu.edu

Dr. Eric Boyer, Assistant Director

High Pressure Combustion Lab

University Park, PA 16802

Phone: (814) 863-2264

Email: jeb19@psu.edu

Diagnostics - Micro-Thermocouples and Heat Flux Gauges

Micro-Thermocouples

The HPCL houses a facility for the fabrication of custom micro-thermocouples. Depending on the thermocouple type and size, both spark- or resistive-welding can be utilized while viewing the fines wires under an optical stereomicroscope. High-temperature (Type D) micro-thermocouples from 25-micrometer wire have been fabricated and used with many different energetic material samples; micro-thermocouples as small as 5 microns have been made for special applications.

Total Heat Flux Gauges

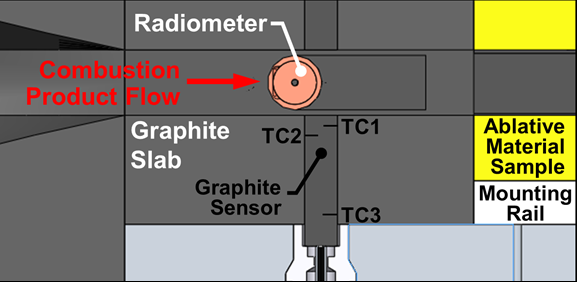

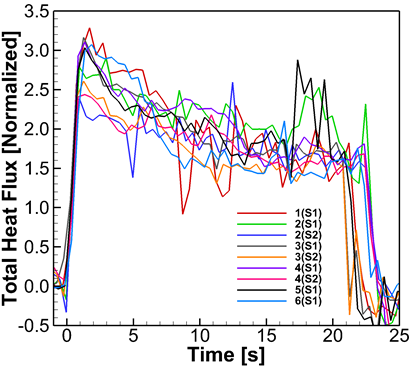

In assessing the performance of ablative internal insulators in solid rocket motors (SRMs), it is useful to measure the total surface heat flux incident on the insulators. The simplicity of this proposition, however, belies the challenges involved in performing such a measurement. Any device installed in an SRM is subjected to both high temperatures and heating rates; therefore, one challenge is the selection of a gauge material that is able to not only survive this environment intact, but also deliver accurate and reliable measurements while exposed to these conditions. A second, and more obdurate, impediment is the introduction of the gauge into the SRM environment in a manner that is minimally invasive and will yield results that are an accurate representation of that environment. To achieve this, a total heat flux gauge using graphite as the sensor material was designed, fabricated, and tested. Multiple micro-thermocouples are embedded at different depths in the graphite sensor, and their recorded temperature histories are utilized in an inverse heat conduction analysis to deduce the total heat flux to and temperature of the graphite surface. The gauge was then employed in six subscale SRM firings performed for a study of ablative internal insulators. This heat-flux measurement technique proved to be both robust, producing repeatable results for each test, and accurate, with uncertainty being no greater than 7% of the deduced flux.

Radiative Heat Flux Gauges

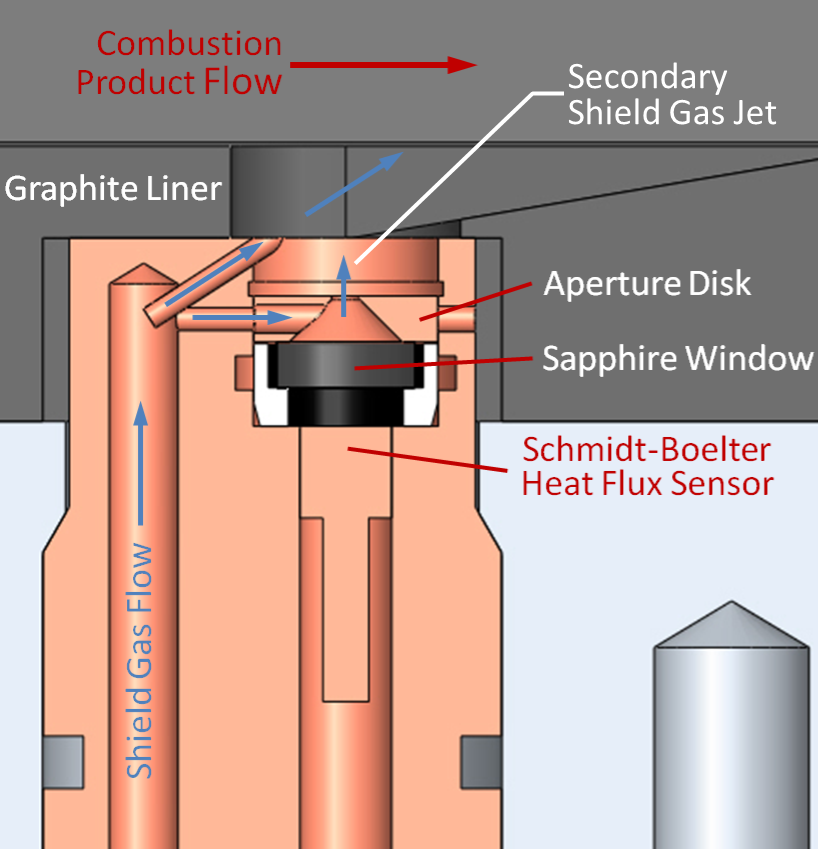

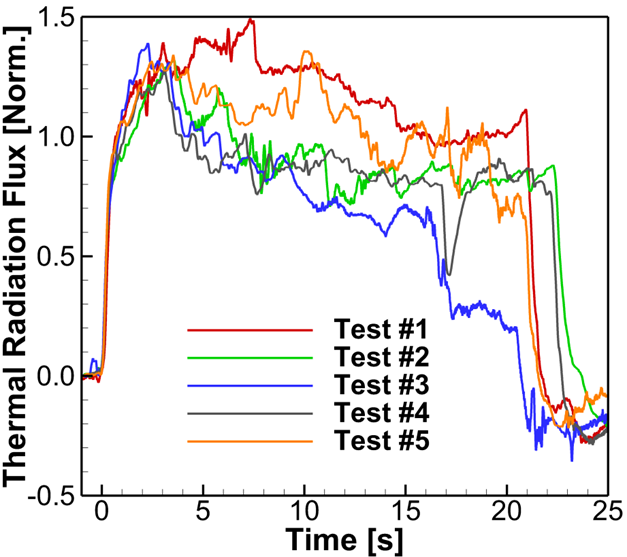

In order to understand the behavior of internal insulators in solid rocket motors (SRMs), it is necessary to observe them under a well-characterized thermal environment. While it is most important to know the total heat flux to the insulator, it is also valuable to know what fraction of that flux is due to its separate radiative and convective components, as each mode is governed by fundamentally different physics and, thus, affects the insulator differently. Therefore, a radiometer was developed to measure the purely radiative component of heat flux in an SRM. In its current form, the radiometer consists of a Schmidt-Boelter-type heat flux sensor isolated from the convective flow of SRM combustion products by a sapphire window, which is mounted in a recess in the wall of the SRM. Condensed-phase particles generated by the combustion of metalized solid propellant are prevented from striking and adhering to the window by two jets of cold inert gas: one injected at an oblique angle to the combustion product flow and another injected normal to the window.